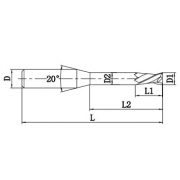

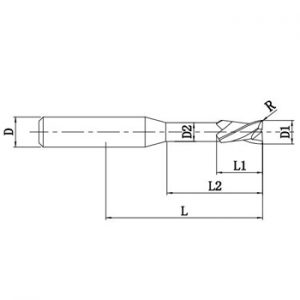

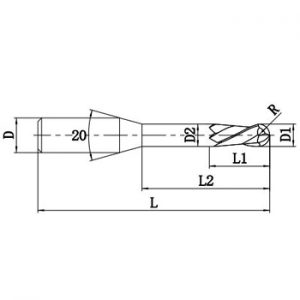

Reinforced stainless steel four edge chamfering cutter-DMGXX4 series

It is suitable for chamfering difficult to machine materials such as stainless steel.

It has higher accuracy and service life than the general model.

- Description

- Inquiry

Reinforced stainless steel four edge chamfering cutter-DMGXX4 series

| It is suitable for chamfering difficult to machine materials such as stainless steel. It has higher accuracy and service life than the general model. | |||||||||||||||||||||||||||||||||

| Tool material: Cemented carbide (tungsten steel) | Coating: PT | ||||||||||||||||||||||||||||||||

| Size | CED | ANGLE | SHK | OVL | Order No | ||||||||||||||||||||||||||||

| DMGX4036050 | 3 | 60° | 3 | 50 | DMGX4-360 | ||||||||||||||||||||||||||||

| DMGX4039050 | 3 | 90° | 3 | 50 | DMGX4-390 | ||||||||||||||||||||||||||||

| DMGX40312050 | 3 | 120° | 3 | 50 | DMGX4-3120 | ||||||||||||||||||||||||||||

| DMGX4046050 | 4 | 60° | 4 | 50 | DMGX4-460 | ||||||||||||||||||||||||||||

| DMGX4049050 | 4 | 90° | 4 | 50 | DMGX4-490 | ||||||||||||||||||||||||||||

| DMGX40412050 | 4 | 120° | 4 | 50 | DMGX4-4120 | ||||||||||||||||||||||||||||

| DMGX4056050 | 5 | 60° | 5 | 50 | DMGX4-560 | ||||||||||||||||||||||||||||

| DMGX4059050 | 5 | 90° | 5 | 50 | DMGX4-590 | ||||||||||||||||||||||||||||

| DMGX40512050 | 5 | 120° | 5 | 50 | DMGX4-5120 | ||||||||||||||||||||||||||||

| DMGX4066050 | 6 | 60° | 6 | 50 | DMGX4-660 | ||||||||||||||||||||||||||||

| DMGX4069050 | 6 | 90° | 6 | 50 | DMGX4-690 | ||||||||||||||||||||||||||||

| DMGX40612050 | 6 | 120° | 6 | 50 | DMGX4-6120 | ||||||||||||||||||||||||||||

| DMGX4086060 | 8 | 60° | 8 | 60 | DMGX4-860 | ||||||||||||||||||||||||||||

| DMGX4089060 | 8 | 90° | 8 | 60 | DMGX4-890 | ||||||||||||||||||||||||||||

| DMGX40812060 | 8 | 120° | 8 | 60 | DMGX4-8120 | ||||||||||||||||||||||||||||

| DMGX4106075 | 10 | 60° | 10 | 75 | DMGX4-1060 | ||||||||||||||||||||||||||||

| DMGX4109075 | 10 | 90° | 10 | 75 | DMGX4-1090 | ||||||||||||||||||||||||||||

| DMGX41012075 | 10 | 120° | 10 | 75 | DMGX4-10120 | ||||||||||||||||||||||||||||

| DMGX4126075 | 12 | 60° | 12 | 75 | DMGX4-1260 | ||||||||||||||||||||||||||||

| DMGX4129075 | 12 | 90° | 12 | 75 | DMGX4-1290 | ||||||||||||||||||||||||||||

| DMGX41212075 | 12 | 120° | 12 | 75 | DMGX4-12120 | ||||||||||||||||||||||||||||

Xingxin Longteng technology specialty manufactures and supplies a full line of both and custom leather cutting knives and blades, Has beenknown in manufacturing of carbide knives and blades for ten years.

All of our standard leather cutting knives are manufactured to exceed the exact OEM standards.

Company Information

10 years of experience in the manufacture of industrial blades

Blade dispenser enables blades to be safely removed individually

Customer-specific livery possible and indidual packaging supper sharpness and long cutting life

Single-sided and double-sided blades are available

Materials and hard coating to customer specification